The Short Answer – Yes.

With very few exceptions, ExpandOS is a perfect fit for your packaging needs. ExapndOS is used to ship everything from fragile glass to heavy concrete and metal parts. We aren’t perfect for every situation but can likely help meet your packaging needs in a very cost-competitive manner.

What Problem Are You Trying To Solve?

We ask this question of each of our Customers. It helps to know why, exactly, you are using packaging so we can decide whether one of our ExpandOS™ grades can fit your situation.

- Protection – ExpandOS™ can hold items in place during shipment while providing excellent shock protection. We can provide protection for any item’s size, shape, or weight that can be shipped via parcel services.

- Cost – Always a consideration. ExpandOS™ is usually less expensive than foam-in-place or air bubble packaging while offering the same or better protection. For items requiring less protection, we are typically at cost parity and oftentimes less expensive than many dunnage alternatives on a total cost basis.

- Labor – Labor has always been a factor in making a packaging selection. ExpandOS™ are very easy to use and are often faster to apply to shipments than other alternatives requiring significant time wrapping or positioning alternative packaging options.

- Green – ExpandOS™ offers a less expensive and paper-based alternative to air bubble packaging and foam in place and is cost-competitive against all packaging alternatives on a total cost basis.

- Presentation – Every package is an opportunity to thrill or disappoint your customers. ExpandOS™ sends a strong message of innovation and a commitment to sustainable alternatives while being brandable. What message are you sending your customers now?

Typical Setups

ExpandOS™ is able to work with any setup needed for your operation. We have a full set of tools to help implement ExpandOS™ in a way that preserves or improves operational efficiency.

Over Conveyor Line

The Expander unit can be placed over a conveyor to dispense ExpandOS™ as boxes move past. The Expander hopper can also be raised or lowered based on the height of your conveyor and the typical size of the boxes being filled. This setup can also be fully automated by singulating boxes, measuring required packaging material, and dispensing it autonomously. The Expander unit sets up in about 10 minutes and plugs into a standard 110v outlet.

Workstation Setup

Each Expander unit is fitted with an adjustable height workstation table for cases where you need to be able to dispense packaging adjacent to a work table. Additionally, the Expander with integrated workstation table can be used as an independent workstation, placed in any area convenient for the operation. The Expander unit itself takes up about 3’ x 3’ of floor space and is ~6’ in total height. Both the worktable height and the hopper dispensing can be independently adjusted to accommodate any size box from very large to very small.

High Volume Automation

Depending on required cycle times and box sizes, we may implement our high-speed rotary Expander to facilitate automation installations. In this case, the Rotary Expander is placed over the conveyor line, and boxes are conveyed beneath it in order to dispense ExpandOS™.

Other Setups

We also offer small workstation-sized hoppers for areas where box counts are very low. In cases where you need to fill large boxes on a very short cycle time, we also offer large overhead hoppers with volumes of ~100CF.

Contact us today to learn more about how ExpandOS™ can help you streamline your operation.

THE ULTIMATE SOLUTION FOR PACKAGE PROTECTION.

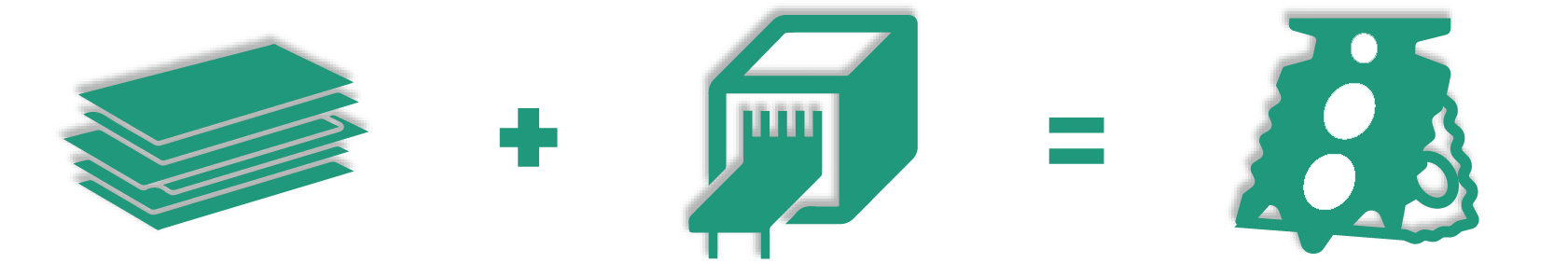

HOW EXPANDOS™ WORKS

WE HELP YOU DECIDE WHICH EXPANDOS™ IS BEST FOR YOU

WE SHIP YOU:

EXPANDOS™ IN A BUNDLE ON A PALLET

+ one pallet makes 1000cF of material

AN EXPANDER MACHINE

+ plugs into standard outlet

+ sets up in 10 minutes

YOU MAKE EXPANDOS™

AS YOU NEED IT!

+ up to 9.6cF per minute!