Lighting Fixture Manufacturer Cuts Labor and Reduces Packaging Costs With ExpandOS™

The California based manufacturer of lighting fixtures was using foam in place as their internal packaging solution.

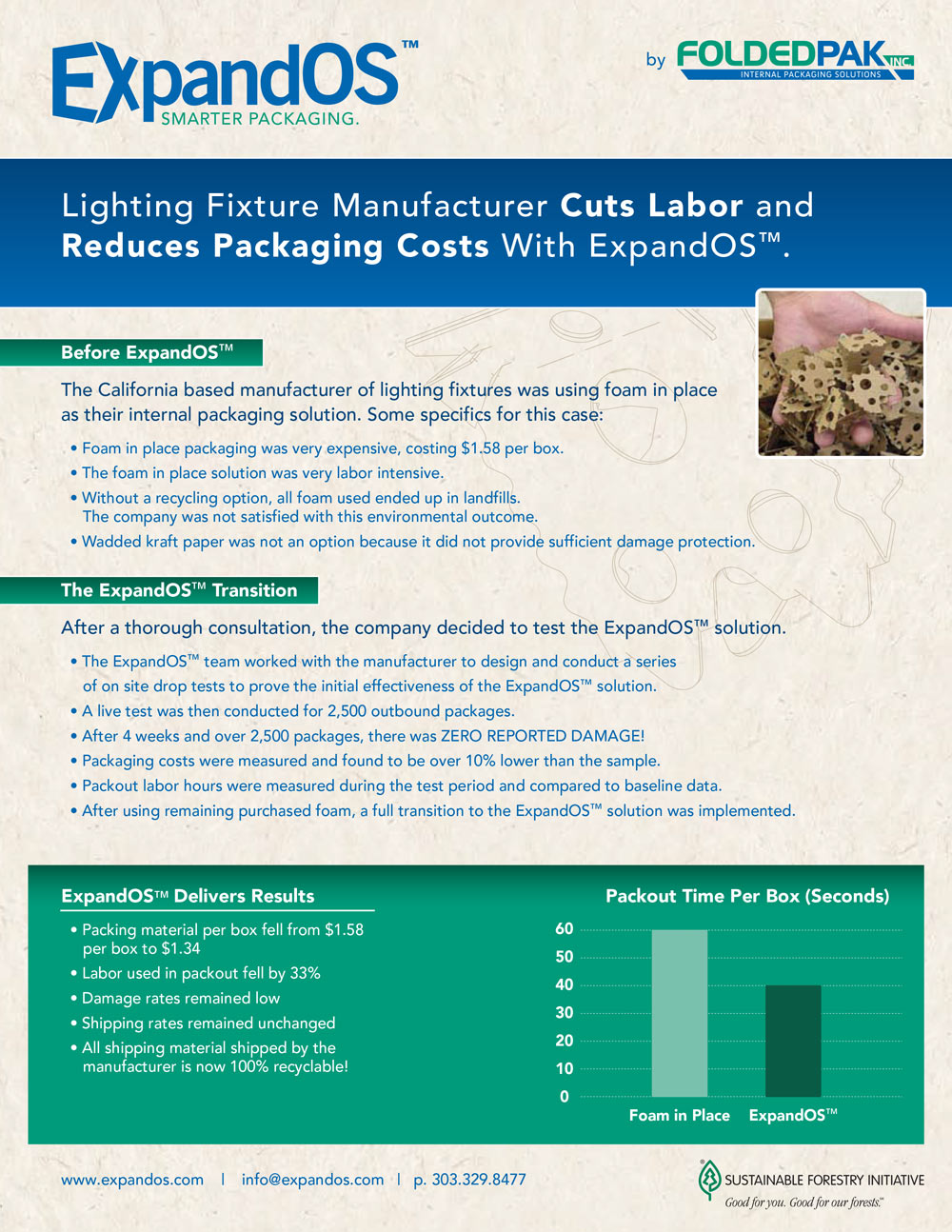

- Packing material per box fell from $1.58 per box to $1.34.

- Labor used in packout fell by 33%.

- Damage rates remained low.

- Shipping rates remained unchanged.

- All shipping material shipped by the manufacturer is now 100% recyclable!

Biggest US Retailer Tells Supplier Fix Damage or Lose Business - Recommends Using ExpandOS™

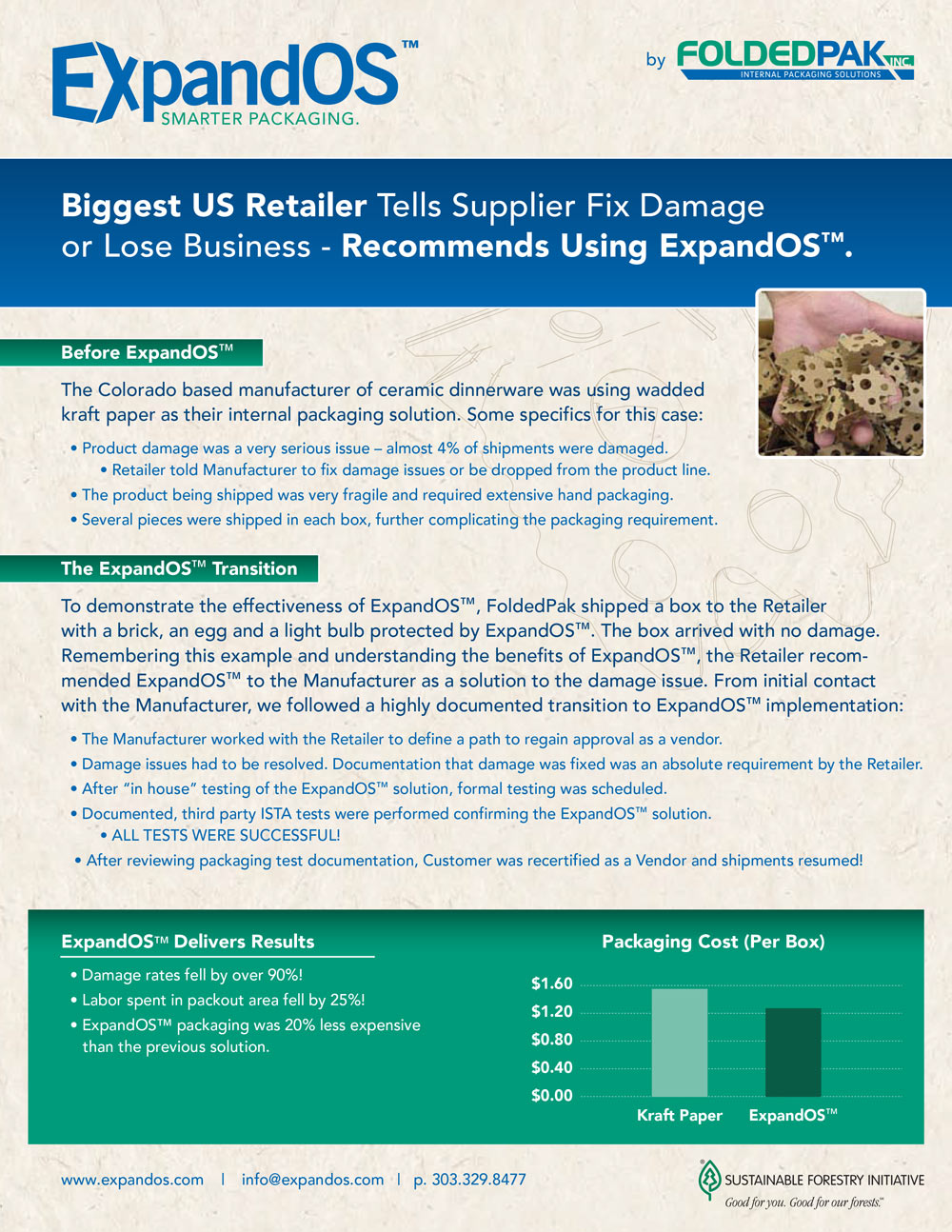

- Damage rates fell by over 90%.

- Labor spent in packout area fell by 25%.

- ExpandOS™ packaging was 20% less expensive than the previous solution.

To demonstrate the effectiveness of ExpandOS™, FoldedPak shipped a box to the Retailer with a brick, an egg and a light bulb protected by ExpandOS™. The box arrived with no damage. Remembering this example and understanding the benefits of ExpandOS™, the Retailer recommended ExpandOS™ to the Manufacturer as a solution to the damage issue.

To Resolve Damage and High Packaging Costs – Automotive Lighting Manufacturer Chooses ExpandOS™.

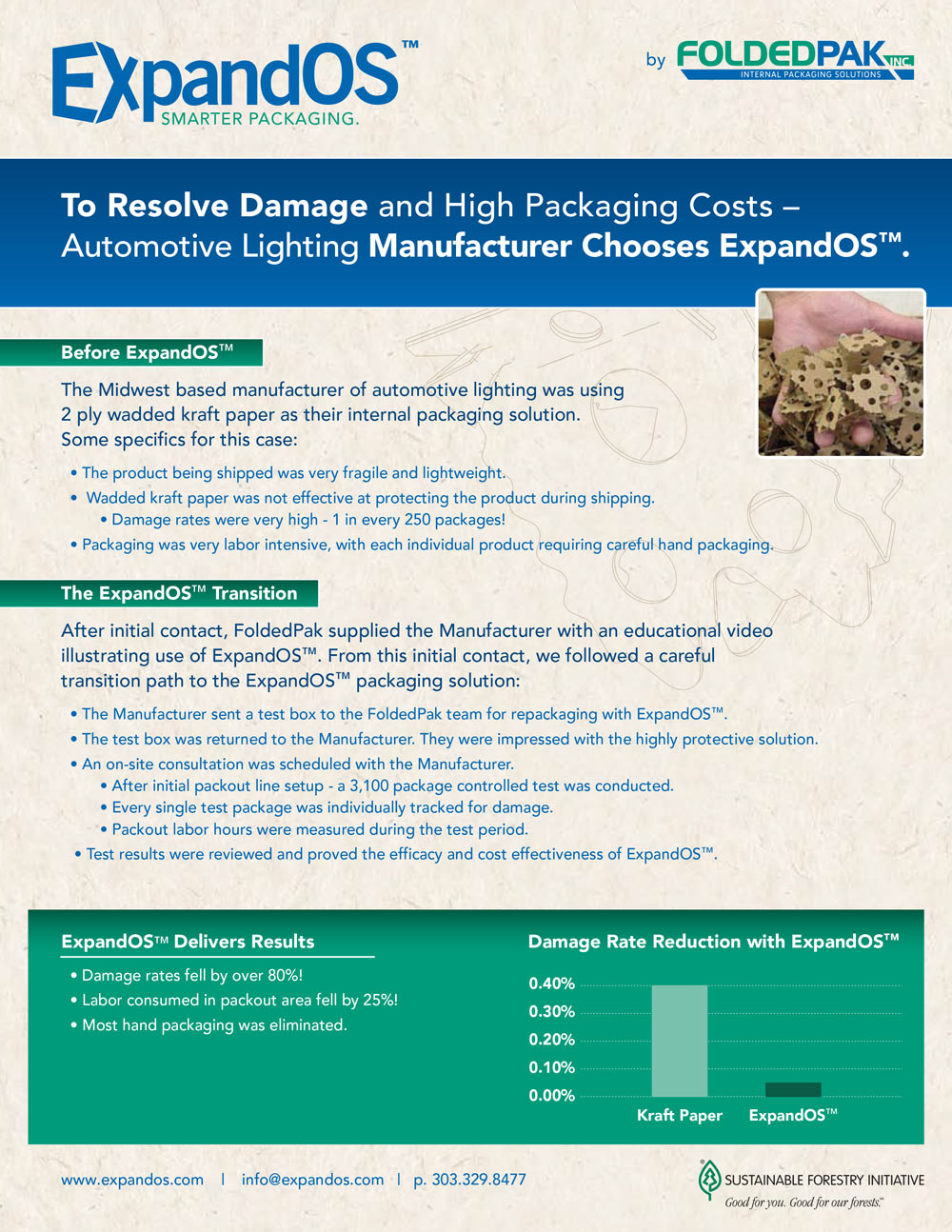

The Midwest based manufacturer of automotive lighting was using 2 ply wadded kraft paper as their internal packaging solution.

- Damage rates fell by over 80%.

- Labor consumed in packout area fell by 25%.

- Most hand packaging was eliminated.